Phone: (914) 381-2400E-Mail: customerservice@marvalindustries.com

Understanding what specialty plastic compounding is can help a business make smart decisions while designing plastic parts. Simply put, compounding is a process that blends plastics with a variety of additives that enhance the final properties of plastic parts. Enhancements are custom-tailored depending on the abilities needed by the manufacturer. For instance, glow-in-the-dark can be added to one job, whereas the other gets improved UV resistance. For the best specialty compounding NY has, do not hesitate to give our team a call.

The first step of the process is to choose a material. We must choose a base polymer, and there are several options to choose from. Manufacturers need to pick a base polymer that is conducive to the desired application the part will perform. After selecting the base material, users then must decide which additives to include in the compounding process. Please speak with our team about color options, strength, chemical resistance and more. We customize each job we do to fit the needs of our clients.

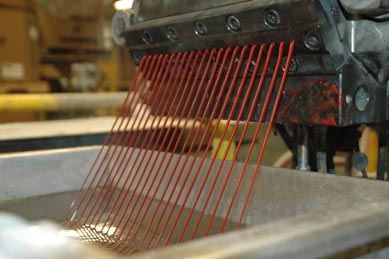

After the two materials are picked, the two are introduced to a mixing blender that has heated screws that mixes and melts components. The mixture is fed through an extruder and becomes individual strands, like yarn. The plastic is left to cool, and then it is cut into pellets. Now it is ready for use.