Phone: (914) 381-2400E-Mail: customerservice@marvalindustries.com

Have you ever wondered how glow-in-the-dark works? We have all seen plastic that glows, but do any of us really know how it works? A glow-in-the-dark product needs to be charged, which can be done with UV rays from the sun or most household lightbulbs. Once fully charged, the glow can last for upwards of ten minutes before having to be charged again. Because of modern technology, the glow can last for up to several hours.

Any glow-in-the-dark product contains some amount of phosphor. This is a substance that can radiate visible light after it becomes energized. Phosphor is found in a wide array of residential and commercial products, but the two most common places are screens (TV, computer, phone) and fluorescent lights. Within a TV, electron-beams strike the phosphor, which energizes it.

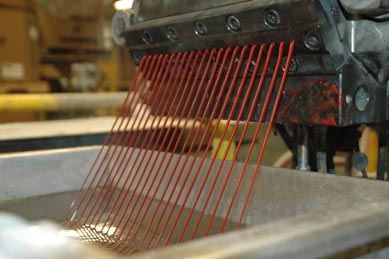

To make glow-in-the-dark plastic, you need to use a type of phosphor that can be energized by normal light and also has a long persistence. Two phosphors that contain these properties are strontium aluminate and zinc sulfide. Strontium aluminate is a newer material, and it provides a super glow for plastic parts. This material is known to have a longer light when compared to zinc sulfide. Phosphor is mixed into plastic using masterbatch or specialty compounding, and then it is molded into glow-in-the-dark plastic.