Phone: (914) 381-2400E-Mail: customerservice@marvalindustries.com

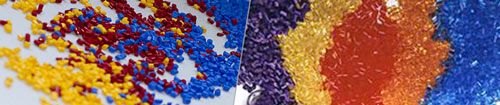

Coloring plastic with use of masterbatching allows for companies to be innovative when it comes to product design. The field of coloring plastics is highly technical, and as a result it has the ability to create custom colors at an incredibly high quality. Innovation is possible by having different types of masterbatching. Each type has its own perks and downsides. Contacting a professional color masterbatch company will help you to make the best decisions about creating products.

Special effects masterbatching allows for plastic products to take on the look of different materials. With this process, pigments and/or fillers are used to give plastic a marble, wood, or metallic look. Glitter can be added to the color to give the product a special sparkle. This type of masterbatch can also create colors that change as a result of temperature or ultra-violet lighting.

Special effects masterbatching allows for plastic products to take on the look of different materials. With this process, pigments and/or fillers are used to give plastic a marble, wood, or metallic look. Glitter can be added to the color to give the product a special sparkle. This type of masterbatch can also create colors that change as a result of temperature or ultra-violet lighting.

Heat reflective masterbatching includes a specialized technology the helps to reflect infrared heat. Originally, this was only possible with PVCu, but now the technique is applied to different materials. A product that was created with this method will stay cooler in hot situations (up to 40% cooler). This type of masterbatching is used for products that spend all day in the blistering sun.

Finding out about different types of masterbatching can help you to create a product that is truly innovative.