Phone: (914) 381-2400E-Mail: customerservice@marvalindustries.com

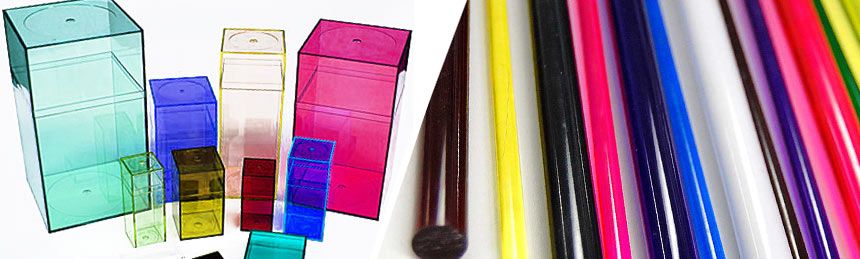

Creating colored plastic products is a necessity in our day in age. Many different companies use plastics to make products, and the vibrant, consistent colors they use helps to bring their products to life. Can you imagine how bland the world would be if all plastic items were either white, black, or transparent? Being able to create high definition, colored products is by no means easy, and it takes a professional company with top of the line machines and computer programs to be able to match and produce desired colors. The challenges that stand in the way of colored injection molding, especially in terms of mating parts, are not an issue for professional masterbatch companies.

First, let’s start off by discussing some of the challenges that stand in the way of color consistency. When producing smaller batches, sometimes you have to make the decision between color consistency and custom colors. For higher volume products (usually more than a ton of a material), color consistency is not such an issue. Considering the batch is bigger, it is easier to blend to a consistent color, as opposed to small batches. When working with small batches, there are two main rules to follow: first, you should be choosing a predefined color. This is a good place for you to start because the color is established, rather than first having to be created. The second thing is to use raw materials that are available to you. Assuring you have the right raw materials will allow making consistent colors for small batches. Knowing the proper raw materials is difficult, so speaking with professional color compounding companies can help give you answers. For getting proper color for large batches (usually in the hundreds of thousands) there are two rules as well: use a pre-fabricated compound and mix masterbatch with natural materials. Color compounding companies have access to the compounds and natural materials. Large quantity batches are no issues for these companies.

Regardless of the amount of materials being produced, perfect color matching is rather important for the success of a product and business. Knowing what it is you are doing helps you to have a strong conversation with a plastic coloring company. Again, if you are doing low volumes you must navigate between custom colors and color consistency. For large volume production this balancing act isn’t needed. Speak with a local professional today, so they can help you bring your products to life (whether you are making 100 items or 100,000 items).