Phone: (914) 381-2400E-Mail: customerservice@marvalindustries.com

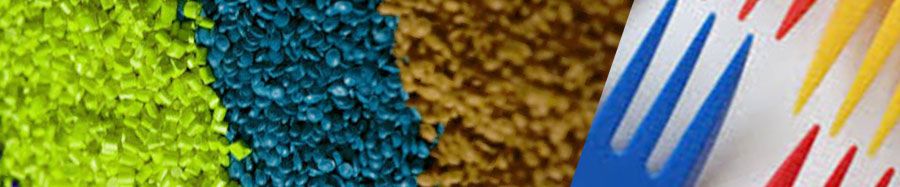

When you go to any department, hardware, or grocery store, you will most likely encounter things that are made out of colored plastic. Usually, people pass these products and goods and don't think twice about how the plastics are colored. These shoppers tend to think that the color process is an easy one, and that is simply not the case. Making plastics with color compounding takes skill and proper machinery.

When working with molded-in color, first, one must take into account chemical compatibility that goes along with the base resin. This will directly affect the colorant system that is chosen. Another factor in picking the system is the temperature and stress that goes on while forming the plastics. Different plastics are created and molded under different conditions, and so color matching works on a case-by-case basis. Picking the wrong coloring system will hinder the durability of the product as well as the ability to keep cost down. Many factors go into making this decision, and each one is as important as the other.

After a system is picked, it becomes possible for a color compounding company to move to another round of issues that must be dealt with. The company must decide if the final product will be molded or if it will be a compounded product (this means that color has been added uniformly into the raw materials). In order to create compounded products one must add color concentrates to the base resin. This is done before molding the part. When adding color concentrates, one must pick between, pellets, powder, or liquid. Not only must one pick the appropriate concentrate, but that person must also make sure that ratios are correct. If too much or too little is added then the desired color will not be achieved. Usually, small amounts of concentrates are combined with natural-colored polymers.

The next time that you see colored plastic for sale take a moment to think about all the time and money that went into making the product the way it is. Without colored plastics, our world would be a little less colorful. If you ever find yourself in need of a masterbatch company who can color plastic, make sure you find a company who knows what they are doing. Above, we only went over some of the considerations these companies must make when creating colorful, vibrant plastics, so make sure you hire someone who can fully explain the process.

Related Reading